Degradable vacuum formed sheet metal has rapidly become a new favorite in industries such as packaging, catering, and healthcare in recent years, mainly due to the tightening of global environmental policies and the increasing demand for sustainable products from consumers.

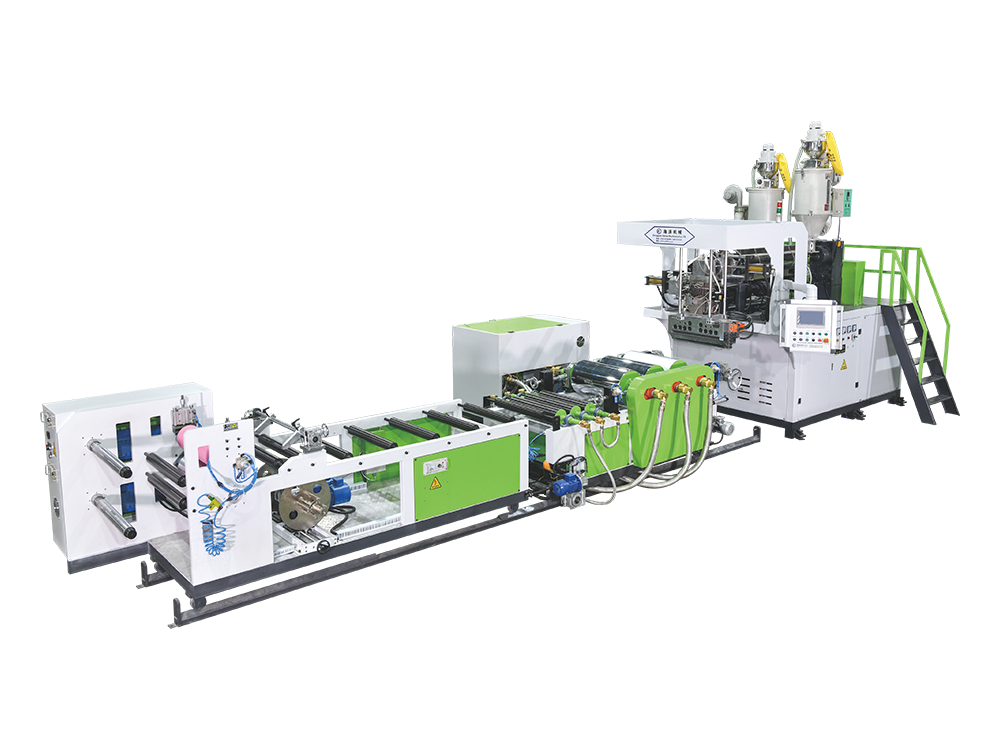

PLA Degradable Blister Sheet Extrusion Series

1. Core driving factors

Policies and regulations are forcing transformation

The global restrictions on disposable plastic products, such as the EU's "plastic ban" and China's "dual carbon" targets, have forced companies to seek alternative solutions. Degradable vacuum formed sheets (such as PLA, PBS, PBAT materials) meet environmental standards and have become the preferred choice for compliance. According to research, over 60% of consumers are willing to pay a premium for eco-friendly packaging, and brands such as Starbucks and McDonald's use biodegradable vacuum formed packaging to enhance their ESG image.

2. Breakthrough in material technology

Application of mainstream biodegradable materials

PLA (Polylactic Acid): Originating from corn starch, it has high transparency and is suitable for food packaging, but its heat resistance is poor.

PHA (polyhydroxyalkanoates): Biodegradable in the ocean, suitable for high value-added fields such as healthcare, with high cost.

Starch based composite materials: Low cost, but require modification to improve strength.

Performance optimization: Through technologies such as nanocellulose reinforcement and blending modification, the impact resistance and barrier properties of some biodegradable vacuum formed sheets have approached those of traditional PET.

3. Expansion of Industry Application Scenarios

Food packaging: fresh food trays, takeaway food boxes (with high demand for oil and water resistant versions).

Electronic products: Buffer lining, piloted by brands such as Apple and Dell.

Medical field: pill blister, biodegradable surgical instrument tray, meeting the dual requirements of sterility and environmental protection.

4. Market growth data

The global biodegradable plastic market is expected to reach approximately 4.5 billion US dollars in 2023 and is projected to exceed 15 billion US dollars by 2030 (CAGR 18%).

Blister sheets account for over 30% of biodegradable packaging, with Asia being the largest producer (China accounting for over 50% of global production capacity).

5. Challenges Faced

Cost bottleneck: The price of PLA vacuum formed sheets is 2-3 times that of traditional PS, and large-scale applications rely on cost reduction through scaling.

The recycling system is not perfect: there are insufficient industrial composting facilities, and some "degradable" products have harsh actual degradation conditions.

Performance trade-off: Traditional plastics still need to be added in some scenarios to maintain functionality, affecting 100% degradability.

6. Future Trends

Mixed material scheme: such as PLA+PBAT+starch composite, balancing cost and performance.

Closed loop recycling pilot: Establish a "production consumption composting" chain in conjunction with the garbage classification system.

Policy subsidies increase: China's tax incentives for biobased material companies promote capacity expansion.

Device application

The rise of biodegradable vacuum formed sheet metal is a joint result of environmental protection needs and technological innovation. In the short term, it is necessary to overcome cost and performance bottlenecks. In the long run, with the improvement of the circular economy system, the process of replacing traditional plastics will accelerate. Enterprises need to pay attention to regional policy differences and material technology iterations to seize market opportunities. Dongguan Haitao Machinery Co., Ltd. is a plastic extrusion equipment manufacturer specializing in the research and development, manufacturing, sales, and service of sheet machines, TPU extrusion machines, and extrusion film extruders. +86-13827271518.